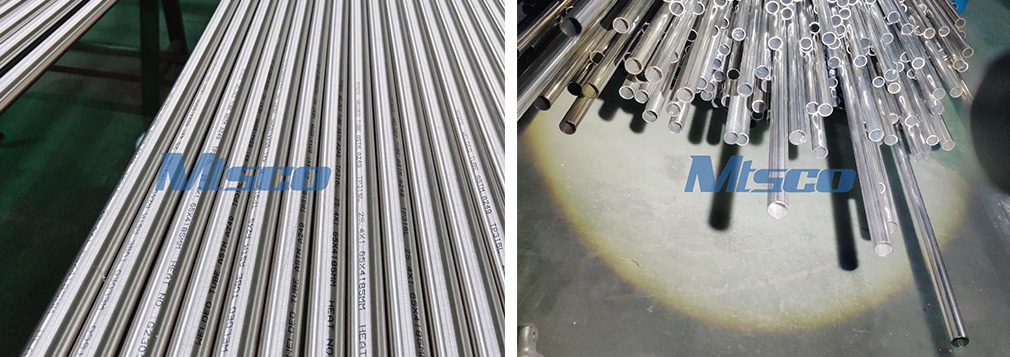

GR2 Titanium Welded Tube, ASTM B337 High Strength for Chemical Industry

Get Quote

GR2 Titanium Welded Tube, ASTM B337 High Strength for Chemical Industry

Titanium alloy is a new important structural material used in the aerospace industry, specific gravity, strength and use of temperature between aluminum and steel, but higher strength than aluminum, steel and has excellent resistance to seawater corrosion and ultra-low temperature performance.

Why Choose MTSCO Welded Tube?

Equipped with state-of-the-art production and inspection equipment, including a CNC bending machine, plate shearing machine, 12m annealing furnaces, pickled pool, ultrasonic eddy current integrated machines, and a physical and chemical lab, MTSCO ensures a comprehensive manufacturing process. The bending machine, with a maximum thickness capacity of 60MM and a length of 12 meters, adds to the precision and versatility of the production process.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Welded Tube

25.4*2.11mm ASTM A213 S30403 Stainless Steel Heat Exchanger Welded Tube

MTSCO is a leading manufacturer who is specialized in seamless tubes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Our heat exchanger tube with pickling and annealing surface is ver......

ASTM A213 / ASME SA213 18BWG TP347 / 347H Stainless Steel Bright Annealed Welded Tube

Material Grade: TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , S31803 , S32750 , S32205 etc Outer Diameter: 3.18-101.6mm Wall Thickness: 0.5-20mm Length: Normally fixed length 6m , can as per customer’s requirement Standard: ASTM A213......

ASTM B725 Alloy 400 / UNS N04400 Nickel Alloy Welded Tube

Alloy 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Alloy 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It ha......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語