ASTM A249 TP304/304L/TP316/316L/316Ti Welded Coiled Tubing

Material: 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435;

Get Quote

Stainless Steel Spiral Wound Tube 304L/ 316L Cold Rolled For Oil Drilling

Material: TP316/L, TP304/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Type: Welded

Hole count: Single/Multi Core

Outer Diameter: 4mm-88.9mm

Wall Thickness: 0.3mm-2.5mm

Length : According to customers’ needs, up to 33000fts

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

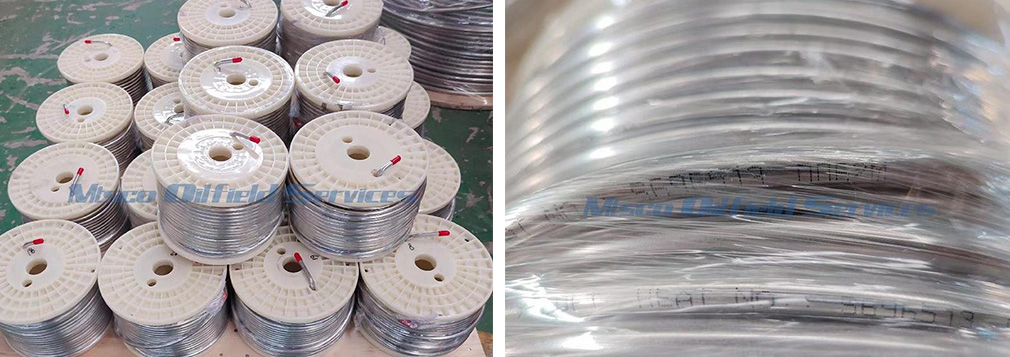

Package: Wooden or iron reel

| Material | Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | - | - | - | - |

| TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | - | - | - | - |

| TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | - | - | - |

| TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | - | - | - |

Stainless Steel 304L and 316L:

Grade 304 is a common material in stainless steel. It is a universal stainless steel with high temperature resistance of 800 ℃. It is widely used to make equipment and parts that require good comprehensive performance (corrosion resistance and formability). With good processing performance and high toughness, it is widely used in industry, furniture decoration industry and food and medical industry.

The carbon content of 304L is lower than 0.03%; The carbon content of 304 is less than 0.08%.

In general, the corrosion resistance of 304L is similar to that of 304, but after welding or stress relief, 304L has excellent intergranular corrosion resistance. 304L stainless steel is low-carbon stainless steel, mainly applicable to welding process. During welding, the low carbon content of 304L stainless steel reduces the carbide precipitated in the heat affected zone near the weld, effectively improves the resistance to intergranular corrosion of stainless steel, and prolongs the service life of stainless steel welds.

316L is a derivative steel of austenitic stainless steel. Because the steel contains molybdenum, its overall performance is better than 310 and 304 stainless steels. Under high temperature conditions, when the concentration of sulfuric acid is lower than 15% or higher than 85%, 316L stainless steel has a wide range of uses.

The Mo content of 316L makes the steel have excellent corrosion resistance and can be safely used in the environment containing Cl - and other halogen ions. As the 316L is mainly used for its chemical properties, the steel plant has slightly lower requirements on the surface inspection of the 316L (compared with 304), and customers with higher requirements on the surface should strengthen the surface inspection. 316L stainless steel also has good chloride corrosion resistance, so it is usually used in marine environment.

Features of 316L stainless steel

1) Excellent high temperature strength;

2) Due to the addition of Mo, the corrosion resistance, especially the pitting resistance, is excellent;

3) The appearance of cold rolled products is glossy and beautiful;

4) Non magnetic in solid solution state;

5) Excellent work hardening (weak magnetism after working);

6) The price is higher than 304 stainless steel.

What is Spiral Wound Tube?

Spiral Wound Tube (SWT) is a type of pipe construction made by alternately winding metal strips with packing. This type of pipe construction is often used to make sealing elements such as packing gaskets and sealing washers to ensure the tightness of pipes and vessels.

Main features and applications:

Structural Design: Spiral-wound pipe construction consists of metal strips and packing that are alternately wound to form a spiral-like structure. This design provides flexibility and pressure resistance.

Material Selection: Commonly used metal belts include stainless steel, copper, and aluminum, while the packing is usually made of soft materials such as flexible graphite, polytetrafluoroethylene (PTFE), etc. This allows spiral wound tubes to be used in a variety of applications. This allows spiral wound pipe to remain stable in a wide range of chemical and temperature environments.

Sealing Performance: Due to its special structure, spiral wound pipe can provide excellent sealing performance under high temperature, high pressure or corrosive media, so it is widely used for sealing pipes, valves and pressure vessels.

Applications: Spiral-wound pipes are mainly used in industrial fields, such as petrochemical, chemical, energy, etc., especially where efficient sealing and corrosion resistance are required.

Why Choose MTSCO Spiral Wound Tube?

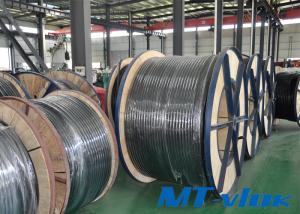

Since 2006, MTSCO has been a dedicated provider of Spiral Wound Tube services, delivering high-quality products to the global geothermal, heat exchanger, shipbuilding, oil, and gas industries. Our extensive range includes materials such as 304, 316, 2205, 2507, alloy 625, 825, and more, manufactured in accordance with various international standards. In recent years, we've achieved significant advancements in control line tubing, downhole control lines, and chemical injection control lines, focusing on the production of welded/seamless continuous tubulars, single/multi-core control lines, capillary tubing, and more.

Opting for MTSCO ensures you benefit from 5 key advantages, providing assurance in your choice:

Firstly, our welded Spiral Wound Tube is available in lengths of up to 33,000fts per coil.

Secondly, our welded Spiral Wound Tube undergoes hydrostatic testing with a maximum pressure of 100MPA.

Thirdly, seamless coiled tubing can achieve a reel weight of up to 120kg.

Fourthly, we offer a diverse range of encapsulated overmoulding materials to cater to varied needs.

Finally, MTSCO's coiled tubing holds the prestigious ISO/PED certificate, serving as a reliable certification of product quality and adherence to standards.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

ASTM A789 S32750 / 2507 super duplex steel coil tubing oil and gas

2507 Super Duplex is a high alloy duplex stainless steel with a PRE (pitting resistance equivalent) value of 42.5 minimum. The grade is characterized by very good chloride corrosion resistance, combined with very high mechanical strength. It is particularly suited for use in aggressive environments ......

1 / 8 Inch TP321H Stainless Steel Welded Super Long Marine Multi-core Coiled Tubing

Where the multi-core coiled tubing used ? Mtsco' s multi-core tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L. The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside a......

9.53mm TP304L / 316L Stainless Steel Welded Super Long Coiled Tubing For Medicine Industry

Material Grade : American Standard: TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard: 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard: X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X5......

15.88mmx1.24mm stainless steel seamless tubing

Type of Stainless Steel Coiled Tubing Stainless steel industry tubing, Super-long coiled tubing, U bend tubing, Pressure tubing, Heat exchanger tubing, Fluid pipe, Spiral pipe etc. High-temperature resistance, Impact resistant and corrosion, Ammonia corrosion resistant Anti-fouling, Dirt-re......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語