ASTM B167 Alloy 600 Nickel Alloy Seamless Pipe

SSNAP07

Price: From $31000-65000USD/TON

Material: Alloy 600, UNSN06600; Alloy 601, UNSN06601; Alloy 625, UNSN06625;

Get Quote

ASTM B829 Alloy 600 / 601 / 625 Nickel Alloy Seamless Pipe

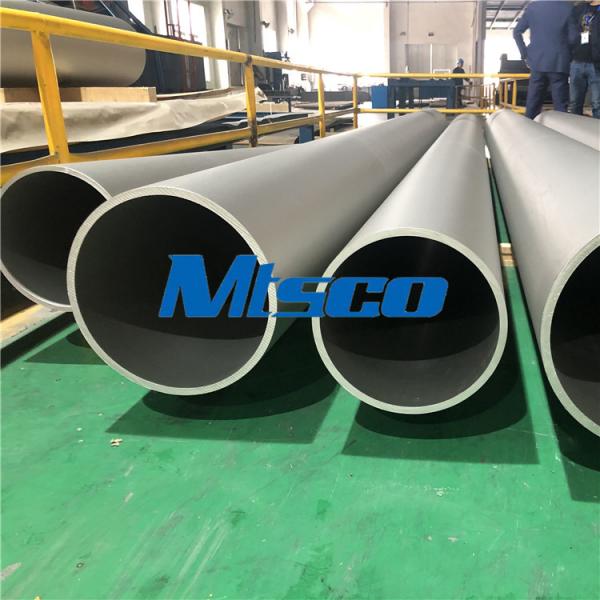

Specifications of Nickel Alloy 600 Pipe:

Grade | Standard | Outside Diameter | 8mm-711mm |

Alloy 600 | ASTM-B444 | Wall Thickness | 1mm-50mm |

Length | ≤20m | ||

Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

Inspection | Appearance/ Dimensional test, PMI; | ||

Certificates | ISO/PED/AD2000/TS | ||

Package | End protection/ Woven bags/ Wooden cases |

Alloy 600 Chemical Composition:

% | Ni | Cr | Fe | C | Mn | Si | S | Cu |

min | 72.0 | 14.0 | 6.0 |

|

|

|

|

|

max |

| 17.0 | 10.0 | 0.15 | 1.00 | 0.50 | 0.015 | 0.50 |

Features of Nickel Alloy 600 Pipe:

Corrosion resistance: Nickel alloy pipe is resistant to a wide range of chemical media, including acids, alkalis and salts, and is particularly resistant to chlorides.

High-temperature resistance: In high-temperature environments, nickel alloy tubes maintain stable mechanical properties and are not susceptible to oxidation and deformation.

Good mechanical strength: Even under extreme conditions, nickel alloy pipes can maintain high strength and toughness.

Ease of Processing: Despite their high strength, nickel alloy pipes can be cut, welded and shaped using modern metalworking techniques.

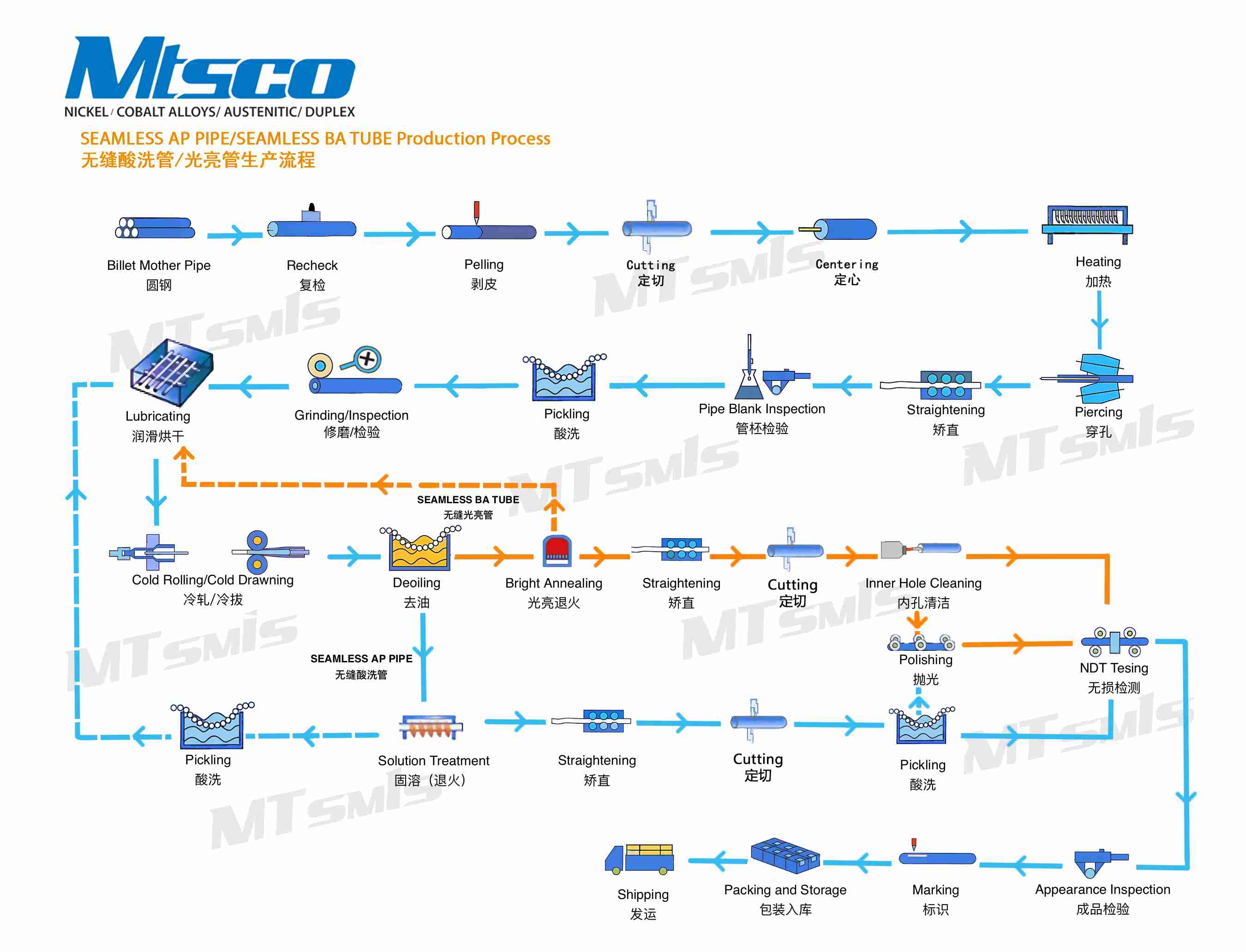

Quality Control of MTSCO Seamless Pipe

Raw Material Quality Assurance

Sourced from reputable steel mills like Baosteel and Tsingshan, our raw materials undergo warranty and PMI checks for quality assurance. Rigorous PMI and other inspections ensure adherence to material specifications.

Production Process Oversight

Our seamless pipe manufacturing encompasses cold rolling, cold drawing, annealing, pickling, and surface treatment. Advanced equipment and skilled engineers oversee each stage, capturing detailed records through photography. Process cards guarantee precision and traceability throughout production.

Pre-Shipment Quality Assurance

Our dedicated QC team performs comprehensive inspections, covering appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are conducted. We also accept third-party evaluations (SGS, TUV, BV) and employ secure packaging and container reinforcement to safeguard goods during transportation.

What is the Production Process of Nickel Alloy 600 Pipe?

ASTM B167 Inconel 600 Nickel Alloy Seamless Pipe Tube

The chemical composition of inconel 600 seamless pipe is mainly nickel, chromium and iron, of which the nickel content is not less than 72%, chromium content is 14%~17% and iron content is 6%~10%. This alloy has high strength and good plasticity in the solid solution state, and can be molded by cold or hot working. Inconel 600 seamless pipe heat treatment temperature range of 1200 ℃ ~ 900 ℃, the cooling mode is water quenching or rapid air cooling. Inconel 600 seamless pipe standard specifications by ASTM B167, its outer diameter range of 6mm ~ 219mm, the wall thickness range of 0.5mm ~ 17%. Wall thickness ranges from 0.5mm to 18mm.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

Alloy C22 / UNS N06022 Nickel Alloy Seamless Pipe For Chemical Industry

Material Grade: Alloy 625/N06625, Alloy 600/ N06600,Alloy 601/N06601,Alloy 718/N07718, Alloy C276/N10276, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Outer Diameter :10.3mm-406.4mm Wall Thickness: 1.24mm-40.49mm Length:Normally fixed length 6m, can as per customer's requirement......

Cold Rolled ASTM B622 Seamless Nickel Alloy C276 Pipe

C-276 is a nickel-based alloy of nickel-molybdenum-chromium-iron-tungsten and is one of the most corrosion-resistant of modern metal materials. It is mainly resistant to wet chlorine, various oxidizing chlorides, chlorinated salt solutions, sulfuric acid, and oxidizing salts, and has good corrosion ......

ASME SB163 / SB423 Nickel Alloy Seamless Alloy 825 Pipe

Apart from nickel being the primary alloying material in the alloy 825 electropolish pipe, the alloy also contains elements such as iron, chromium, titanium, molybdenum, and copper. Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments contain......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語