Nickel Alloy 625 UNS N06625 Seamless Pipe For Aerospace

SSNAP10

Material: Alloy 625, UNSN06625;

Get Quote

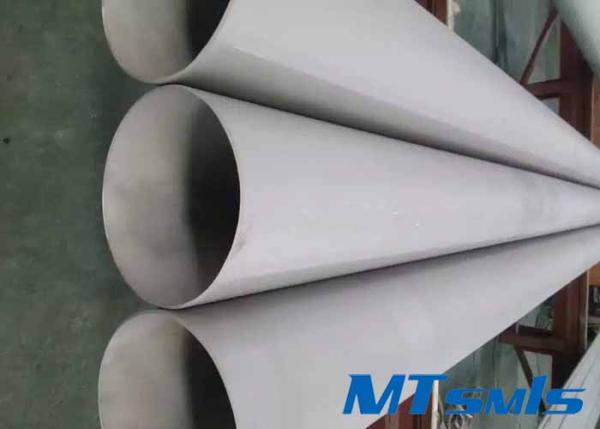

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Why Choose MTSCO Nickel Alloy 625 Pipe?

Nickel Alloy 625 Pipe Chemical Composition:

| % | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

| min | 58.0 | 20.0 | 8.0 | 3.15 | |||||||||

| max | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Nickel Alloy 625 Pipe Physical Properties:

| Density | 8.44 g/cm3 |

| Melting range | 1290-1350℃ |

What Is Feature Nickel Alloy 625 Pipe?

What is Shot Peening for Nickel Alloy 625 Pipe?

AMS 5581F UNS N06625 625 Pipe

Inconel 625, a nickel alloy pipe produced in accordance. pipe made of this material has excellent strength and toughness over most temperature ranges, not only that, it also has excellent corrosion and oxidation resistance, which allows it to maintain a stable working condition in extreme environments.

Inconel 625 seamless pipe is a high-performance alloy synthesized from nickel, chromium, molybdenum, niobium and other elements, with extremely high corrosion resistance and high strength. It can maintain good mechanical properties and corrosion resistance in the temperature range of -196 to 450°C, and is not affected by chlorides, oxidizers, reducing agents, acids and alkalis and other media. It also has excellent resistance to pitting, crevice corrosion, intergranular corrosion and stress corrosion cracking, as well as good processability and weldability

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

Alloy C22 / UNS N06022 Nickel Alloy Seamless Pipe For Chemical Industry

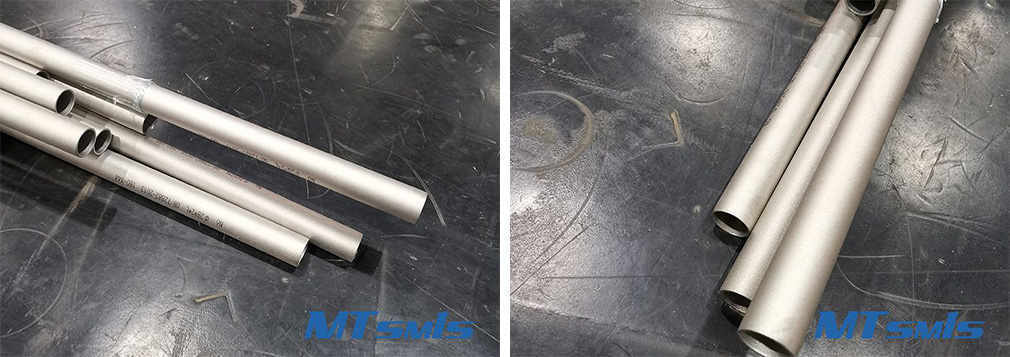

Material Grade: Alloy 625/N06625, Alloy 600/ N06600,Alloy 601/N06601,Alloy 718/N07718, Alloy C276/N10276, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Outer Diameter :10.3mm-406.4mm Wall Thickness: 1.24mm-40.49mm Length:Normally fixed length 6m, can as per customer's requirement......

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語