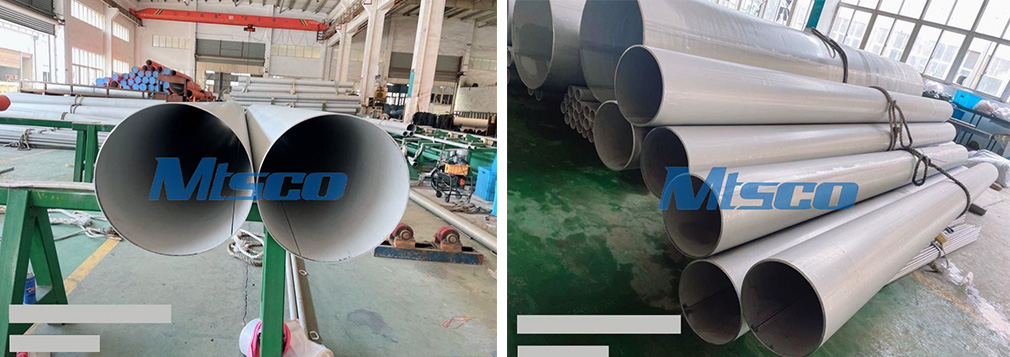

ASTM B619 Alloy C276 Pipe Nickel Alloy Welded Pipe for Strong Acid

SSNAWP01

Material: Alloy C-276,UNSN10276,2.4819;

Get Quote

ASTM B619 / ASME SB619 Alloy C276 Nickel Alloy Welded Pipe

Specifications of Nickel Alloy Welded Pipe, C276:

| Grade | Standard | Outside Diameter | 219mm3000mm |

| Alloy 600 Alloy 601 Alloy 625 Alloy 825 Alloy 800/800H/800HT Alloy C276 Alloy C22 Alloy 400 Alloy K500 Alloy 200 Alloy 201 ... | ASTM-B619 ASTM-B705 ASTM-B725 AMS5796 ... | Wall Thickness | 4mm-60mm |

| Length | ≤12m | ||

| Inspection | Appearance/Size/PMI Inspection NDT:100%X-Ray/ET/UT/HT... Mechanical Testing Third Party Inspection | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

Nickel Alloy Welded Pipe Chemical Composition:

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | - | - | - | - | - | - | - |

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

What Are the Advantages Of Mtsco Nickel Alloy Welded Pipe?

5. Complete certificates - ISO/PED/AD2000 certificates.

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

| Alloy 718/N07718 | ≥550 | ≥965 | ≥30 | ≤363 |

| Alloy 800/N08800 | ≥210 | ≥500 | ≥35 | - |

| Alloy 800H/N08810 | ≥180 | ≥450 | ≥35 | - |

| Alloy 825/N08825 | ≥220 | ≥550 | ≥30 | ≤200 |

| Alloy B/N10001 | ≥310 | ≥690 | ≥40 | - |

| Alloy C22/N06022 | ≥283 | ≥690 | ≥40 | - |

| Alloy C276/N010276 | ≥283 | ≥690 | ≥40 | - |

ASTM B619 Hastelloy C276/C22 Welded Pipe

Hastelloy C276 welded pipe is a very stable nickel-chromium-molybdenum alloy with good corrosion resistance and strength. It has excellent corrosion resistance to chloride environments at all temperatures and concentrations, including hyperthermic and oxidizing salts such as iron and copper chlorides. As a result, this welded pipe has a wide range of applications in the chemical, petroleum, paper and environmental industries.

In contrast, Hastelloy C22 welded pipe is also an excellent nickel-chromium-molybdenum-tungsten alloy, which is better suited to combat harsh chemical environments than the C276 material. It remains stable in harsh environments, including wet chlorine, hydrogen chloride, hydrogen sulfide and chlorine oxide. As a result, it has been warmly welcomed in the chemical, food processing, and medical device industries.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Nickel Alloy Welded Pipe

ASTM B619 / B626 Alloy 230 / UNS N06230 Nickel Alloy Welded Pipe

Material Grade :Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030,Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 Outer Diameter: 3.18mm-101.60mm Wall Thickness: 0.50mm-20.00mm Length: Normally fixed length 6m, can as per c......

ASTM B619 Alloy S / UNS N06635 Nickel Alloy Welded Pipe

1. Material Grade: Alloy S, Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc 2. Outer Diameter: 10.3mm-426mm Wall Thickness: 1.24mm-40.49mm 3. Length: Normally fixed length 6m, ca......

ASTM B622 / B619 Alloy G-30 / UNS N06030 Nickel Alloy Pipe

1. Material Grade: Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030, Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 etc. 2. Outer Diameter: 10.3mm-406.4mm Wall Thickness: 1.24mm-40.49mm 3. Length: Normally fixed length......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語